Why do we use jaw crusher?

2024-07-23 04:26

Why do we use jaw crusher?

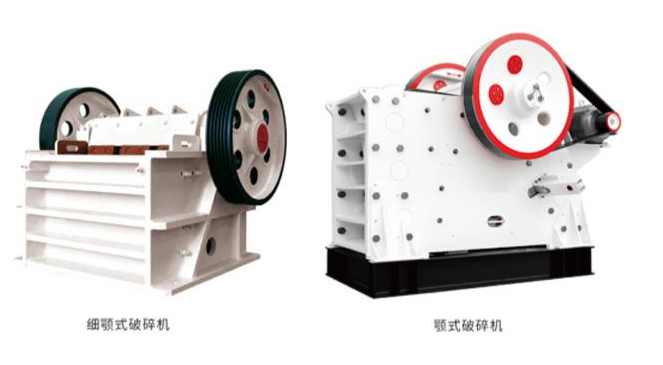

Jaw crushers are mainly used as coarse crushers and medium crushers in mining, building materials, infrastructure and other departments. According to the width of the feed opening, they are divided into three types: large, medium and small. The feed opening width is greater than 600MM for large machines, 300-600MM for medium machines, and less than 300MM for small machines. The jaw crusher has a simple structure, is easy to manufacture, and works reliably.

The working part of the jaw crusher is two jaw plates, one is a fixed jaw plate (fixed jaw), which is fixed vertically (or slightly tilted at the upper end) on the front wall of the machine body, and the other is a movable jaw plate (moving jaw), which is inclined and forms a crushing chamber (working chamber) with a larger upper part and a smaller lower part with the fixed jaw plate. The movable jaw plate performs periodic reciprocating motion against the fixed jaw plate, sometimes separating and sometimes approaching. When separated, the material enters the crushing chamber and the finished product is discharged from the bottom; when approaching, the material loaded between the two jaw plates is squeezed, bent and split to be crushed.

According to the different swinging modes of the movable jaw plate, the jaw crusher can be divided into three types: simple swing jaw crusher (simple swing jaw crusher), complex swing jaw crusher (compound swing jaw crusher) and comprehensive swing jaw crusher.

As for the jaw crusher, although the structural types are different, their working principles are basically similar, except that the movement trajectory of the movable jaw is different. In summary, when the movable jaw plate makes periodic reciprocating motion around the suspension shaft to the fixed jaw plate, sometimes approaching and sometimes leaving, when the movable jaw plate approaches the fixed jaw plate, the ore between the two jaw plates is crushed by the combined action of crushing, splitting and bending and breaking; when the movable jaw plate leaves the fixed jaw plate, the crushed ore is discharged through the discharge port of the crusher under the action of gravity.

Working Principle

When the jaw crusher is working, the movable jaw plate makes periodic reciprocating motion against the fixed jaw plate, sometimes approaching and sometimes moving away. When approaching, the material is squeezed, split, impacted and crushed between the two jaw plates; when moving away, the crushed material is discharged from the discharge port by gravity.

In the process of crushing huge stones into small stones, the first crusher is usually the "main" crusher. The oldest and most sturdy crusher is the jaw crusher. When feeding the jaw crusher, the material is poured from the top inlet into the crushing chamber containing the jaw teeth. The jaw teeth push the material against the chamber wall with great force and crush it into smaller stones. The movement of the jaw teeth is supported by an eccentric shaft that runs through the body frame. The eccentric movement is usually generated by a flywheel fixed at both ends of the shaft. The flywheel and the eccentric support bearing often use spherical roller bearings, which must withstand huge impact loads, abrasive sewage and high temperatures.

Advantages

1. Effectively solve the problem of high operating rate and no maintenance time caused by low output of the original limestone crusher.

2. It can complete the crushing of large pieces of limestone, with a maximum crushing particle size of 1000*1200mm, effectively solving the original problem of "tight limestone supply on one side and large amounts of large limestone stored and unusable on the other side".

3. The mixing uniformity of the two materials is good, and the addition amount of desulfurized limestone is greatly increased. The addition amount can reach 60%, which effectively reduces the cost of raw materials.

4. The power consumption has decreased. The power consumption of 1 ton of limestone decreases by 1-2KWh/t, which can save 100,000 yuan in electricity bills each year.

5. The waste particle size is small, only 2-15mm, which effectively solves the problem of large limestone particle size, frequent blockage of the chute and even affecting the output of the mill.

Get the latest price? We will reply as soon as possible (within 12 hours)