Detailed Explanation Of Fuel Tank Trailer Structure

2024-04-11 04:34

A fuel tank trailer is an oil tanker truck that uses a tractor head to connect the trailer part. The tank semi-trailers mainly consist of a tank body assembly, a frame traveling mechanism assembly, an unloading system, a left and right protection assembly, a rear bumper assembly, a hose storage box assembly, a tank top guardrail, and an operation box assembly. Additionally, they consist of a tool box assembly, electrical system installation assembly, fire extinguisher box assembly, front and rear ladder assembly, ABS braking system assembly, and tank safety accessories.

A fuel tank trailer is an oil tanker truck that uses a tractor head to connect the trailer part. Compared with ordinary single-piece tank trucks, tanker semi-trailers can effectively improve transportation efficiency when transporting oil. With the same tonnage, transportation costs are reduced and fuel consumption is saved.

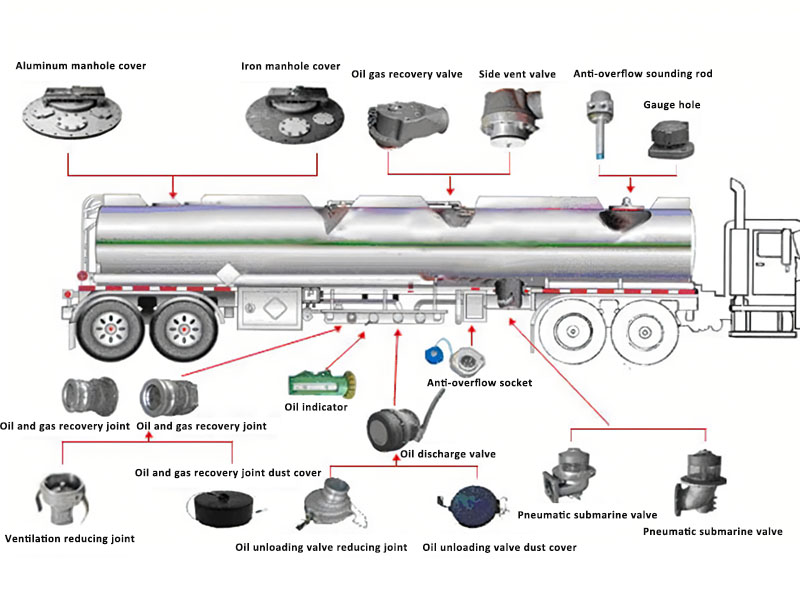

The tank semi-trailers mainly consist of a tank body assembly, a frame traveling mechanism assembly, an unloading system, a left and right protection assembly, a rear bumper assembly, a hose storage box assembly, a tank top guardrail, and an operation box assembly. Additionally, they consist of a tool box assembly, electrical system installation assembly, fire extinguisher box assembly, front and rear ladder assembly, ABS braking system assembly, and tank safety accessories.

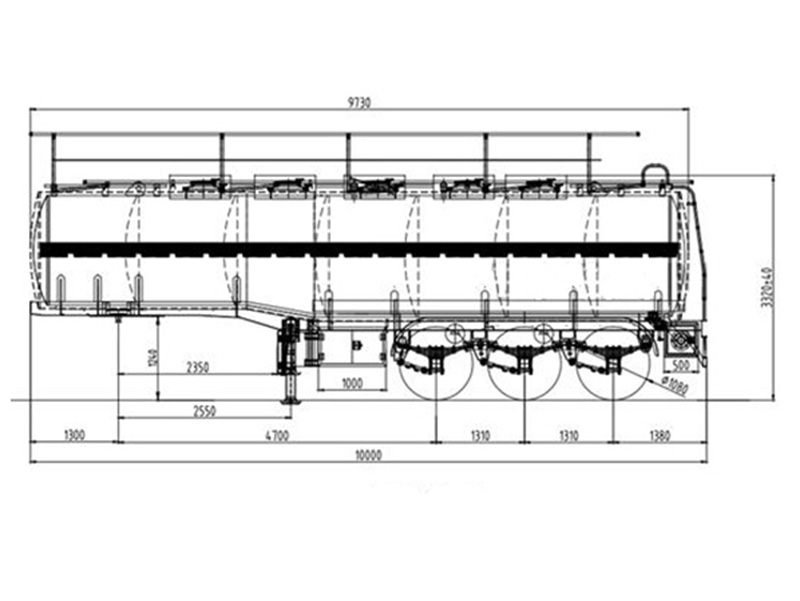

In considering the rear parts of a fuel tanker trailer, they are roughly the same, divided into rear double axles and rear three axles. Depending on specific needs, one can choose a tractor head accordingly. To ensure the highest quality and reliability, it's crucial to collaborate with reputable tanker trailer manufacturers who adhere to stringent safety standards and engineering specifications.

Tanker Trailer Body

1. The oil tanker trailer body is made of 4mm or 6mm high-quality carbon steel produced by the steel company in accordance with national standards. The shape of the tank body is oval or round.

2. Can produce heating and insulation series tanks.

3. The tank is equipped with multiple wave-proof partitions and can hold 1-4 types of oil products.

4. Using high-pressure gas leak testing, the tank has the characteristics of high strength, stable center of gravity, and safe and stable vehicle transportation.

5. According to the purpose of the tanker, centrifugal pumps, gear pumps, and stainless steel pumps can be selected, which have the characteristics of large flow rate and fast suction speed.

6. The tanker trailers can be measured with single-count or double-count flowmeter. It can also be equipped with a tax-controlled computerized refueling machine, a 10-15m automatic telescopic return reel, and a refueling gun. Edible oil products can be measured using a computerized edible oil meter.

Tanker trailers can also choose the following configurations according to usage needs:

1. Oil tank trailer pumping system: The power source of the oil tanker trailer pumping system is the power take-off of the tractor. When loading and unloading, the pump in and pump out functions are realized by opening and closing the valves in the pipeline.

2. Fuel tank trailers insulation system: When the shipping temperature of the medium is high, in order to prevent the liquid medium from freezing, an insulation layer needs to be added to the outside of the tank. The insulation layer is made of glass fiber, which is resistant to high temperatures and has good thermal insulation performance. It is then wrapped with a thin steel plate, aluminum plate or mirror panel on the outside and tightened with a tightening belt for easy maintenance.

3. Tank trailers cleaning pipeline system: When the transported liquid medium is prone to corruption and deterioration, a cleaning pipeline system can be installed to clean the tank after each shipment to ensure the cleanliness of the tank. The system consists of cleaning nozzles, cleaning pipes, valves, joints, etc. When cleaning is needed, connect the connector and open the valve to clean the tank. There is no need for operators to enter the tank, which improves work efficiency and eliminates contamination of the tank when personnel enter and exit the tank.

4. Oil trailers heating system: When transporting media with a high freezing point, a heating system can be installed on the tank. Before unloading, the steam heating medium is passed into the heating pipe to raise the temperature of the medium and melt it to facilitate unloading.

5. Pneumatic guardrail on the tank top of oil trailer: The tank top lifting guardrail designed according to the tank structure has two types: pneumatic operation and manual operation. The manual guardrail is the company's standard configuration, and the pneumatic guardrail is an optional configuration. The pneumatic guardrail is controlled by a cylinder, and its operating switch is located near the ladder. When the button valve is pressed, the guardrail automatically rises.

6. Bottom-loading oil and oil and gas recovery system of crude oil trailer: Bottom-loading oil and oil and gas recovery system is a high-tech energy-saving and environmentally friendly technology, which can be installed according to the needs of users. The bottom loading oil and oil vapor recovery system has the function of realizing the loading and unloading of liquid cargo at the bottom. It can also recover the oil and vapor discharged during the storage, transportation, loading and unloading process of oil products, prevent the volatilization of oil and vapor from causing pollution to the atmosphere, and play the role of eliminating safety hazards.

Maintenance method

1. To ensure the cleanliness of the oil tank, the oil tank and the oil delivery system should be cleaned regularly. The internal and external joints at both ends of the oil delivery hose should be regularly smeared with lubricating oil. The oil pipe should be cleaned in time after each work is completed to ensure that the inside of the pipe is clean.

2. The use and maintenance of the oil pump must be strictly carried out in accordance with its use and maintenance instructions.

3. Before refueling operations, a lightning rod must be inserted into the moist soil. The ground tape of the fuel tankers should be grounded. Good static electricity conductivity should always be maintained during the operation.

4. Safety valves and filter nets should be checked and cleaned frequently.

5. Oil tanks and pipeline systems should be cleaned regularly. Regularly check whether the joints of the piping system are well connected and sealed reliably.

Get the latest price? We will reply as soon as possible (within 12 hours)